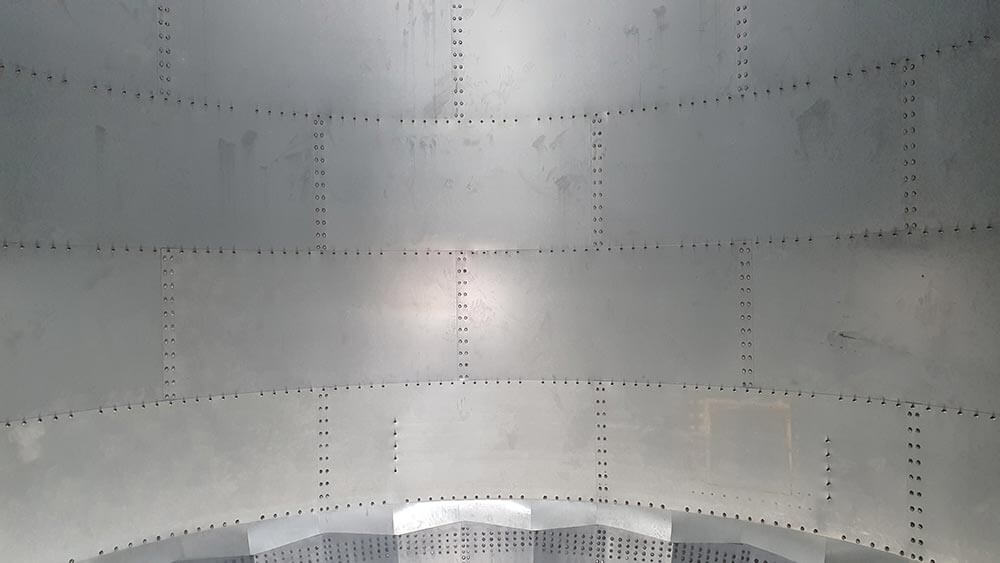

We are introducing a new flat metal sheet kit for lining the inside of silos, ensuring a completely smooth surface.

The new flat metal sheet kit developed by Silos Spain is specially designed to reduce product friction on silo walls, thereby enhancing material flow.

Cohesive bulk materials that tend to agglomerate often stick to silo walls. Factors such as moisture and storage time further affect flow properties. The smooth lining reduces friction, allowing the material to flow more easily.

Although our silo walls are very flat (with a wave pitch of 104 mm and a depth of 13 mm), which prevents the grain from remaining on the walls during the unloading process, there are projects that still require completely smooth walls, particularly in the feed and granulated products sectors.

Our inner liner can be installed in both flat-bottom and hopper silos and is available for any silo diameter. See technical data sheet

Currently, the flat sheet metal lining is being installed in the soybean meal silos at a feed factory in Guadix, Spain. For more details about this project, please visit the link: Project Details

Under construction: Silo featuring our new flat metal sheet lining at feed factory in Guadix, Spain