Competitive Advantages

Quality

Safety

Sustainability

Innovative Metal Coating: ProMag

We use high-strength steel ranging from 350 MPa for ferrules up to 600 MPa for reinforcements, with an innovative metal coating called ProMag.

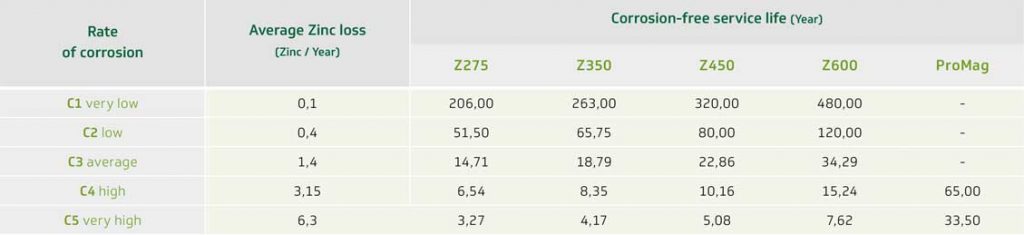

In the manufacturing of our silos, we exclusively employ sheet metal with the cutting-edge ProMag metal coating. This revolutionary alloy of aluminum, magnesium and zinc provides exceptional protection in the harshest conditions while extending the material’s lifespan. ProMag boasts excellent corrosion resistance, over 10 times superior to galvanized steel and more than 5 times better than Z-600 galvanized steel (600g/m2), according to ISO 9223 standards.

Beyond its technical properties, ProMag is an environmentally-friendly choice, using a reduced amount of zinc compared to pure zinc coatings. Hence, it stands as the most profitable alternative for the post-galvanization process.

High-stength stiffeners

Our high yield strength stiffeners made in galvanised steel improve the weight of the silo which makes for easier assembly and optimises the silo behaviour against the action of external agents.

Smoother wall rings

The wave design with a gentle radius means better silo cleaning improving material unloading without any residue remaining so products are not contaminated.

Why EUROCODE

Nowadays, the two most often used standards worldwide to calculate silos are the European EUROCODE and the US ANSI standard. Although they both offer valid and proven results throughout the world, they are based on different calculations. Silos designed pursuant to EUROCODE are more robust. The increase in weight means an increase in safety and reliability. This, along with the excellent materials and coatings used by Silos Spain, increases the service life of your system which also increases your profitability.

Roof protection systems

All of the means of access and maintenance on our silos have been designed for user safety and ergonomics and are designed pursuant to standard UNE-EN ISO 14122-2.

For storage plants in extreme weather zones, we have roof protection systems that prevent the entrance of snow into the silo through the chimneys as well as any accumulation in susceptible areas. All of our silos feature protective elements to prevent birds from entering.

Quality bolts

We install 8.8 quality bolts minimum on all of our silos and 3 different coatings, depending on the geographic needs. Saline environments: GEOMET bolts + sealer for 1000 h corrosion resistance in a salt spray chamber. Non-saline environments: bichromate bolts + sealer for 400-500 h corrosion resistance in a salt spray chamber. Upon request: hot-dip galvanised bolts with a minimum average coating thickness of 40-50 micras, depending on the galvanisation standard.

Quality and Safety

Our grain handling equipment meets all safety and quality requirements:

- It is made of S350GD galvanized steel with a Z-600 coating providing unbeatable weather protection.

- It is modular and bolted construction.

- Its performance is guaranteed.

- Components from leading brands.

- Its reliability is assured by its mechanical simplicity and the quality of the components.

- It is silent and safe.

- We will meet any required safety regulations: European Directive – machinery. Rules for the selling&trade, commissioning of machines. European Directive – protective systems – potentially explosive atmospheres. Machine safety standard, general principles for the design and assessment of risk and for risk reduction. Equipment and systems for continuous maintenance, safety requirements and electromagnetic compatibility. Machine safety. Permanent means of access to machines and industrial facilities. Low voltage directive.