Recommendations for the storage of wheat in a metal silo.

The proper performance of all the processes involved in the post-harvest handling of grains and oilseeds, which includes their storage, transport and post-harvest conditioning, is essential to maintain the highest quality.

Adequate conservation measures are essential, since deterioration during storage can be very rapid due to the effects of grain respiration, which can cause the development of fungi and insects that proliferate easily in optimal humidity and temperature conditions.

Different cereals may require specific conditions. In the case of wheat, there are 3 important factors to be controlled in order to keep it in optimal conditions:

- Innocuousness (insecticide residues and presence of mycotoxins), a necessary condition to ensure food safety.

- Need to segregate by quality.

- The effect of drying on the quality of the wheat. It is necessary to control the drying temperatures, so that the gluten proteins are not damaged, as the process is not reversible.

POST-HARVEST HANDLING OF WHEAT AND ITS EFFECTS ON QUALITY

The main processes involved in the post-harvest handling of wheat are cleaning, storage, aeration, drying and pest control. If all these processes are adequately performed, the highest quality of wheat will be maintained.

CLEANING

Before storage, the cereal is cleaned by a pre-cleaner, that removes dust and light particles from the wheat (grains of other cereals, stones, straw, etc.). This process leaves more room for the storage and leaves the wheat clean, improving its conservation.

STORAGE

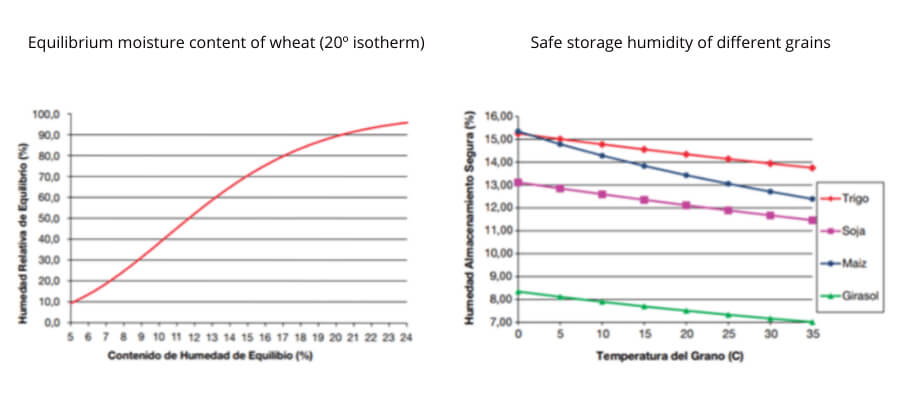

Fungi and insects are the main cause of the loss of grain quality during post-harvest. To reduce the damage they may cause, it is very important to control the relative humidity, producing unfavorable conditions for their development.

When the relative humidity is less than 67%, the storage is safe, since the development of fungi occurs at 71% or more.

Source: ASAE, 2001

The equilibrium moisture content determines the humidity to which a grain can be dried under particular conditions of relative humidity and air drying temperature.

To monitor the condition of stored grains, we use thermometry, a technology that allows us to detect temperature increases, enabling us to correct them by aeration, which avoids grain damage.

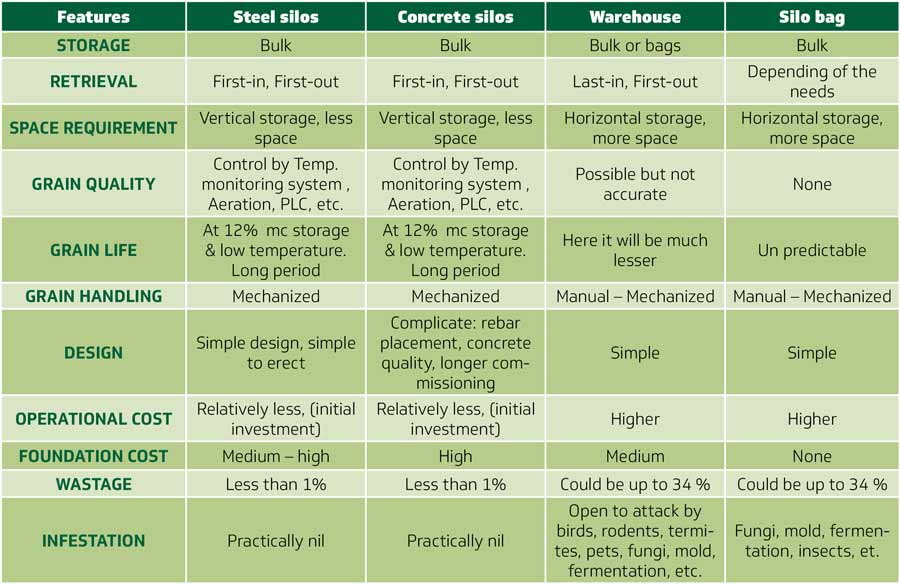

How to choose the most adequate grain storage system

Whilst the choice of grain storage methods is wide, the most popular ones are steel silos, concrete silos, storage warehouses and bag silos among others.

Features of Main Storage Systems

Galvanised sheet metal silos are currently the best alternative for grain storage thanks to their versatility, easy assembly, hygienic handling and low storage cost.

AERATION

Aeration helps to maintain grain quality during the storage by forcing movement of ambient air through the grain mass.

This process allows us:

- To keep the grain temperature as low as possible, thus favoring longer storage periods.

- To maintain a uniform temperature, thus avoiding areas of humidity in the grain stored in a silo.

- To dry specific areas of humidity. This requires a lengthy operating time and an adequate air flow. Drying wheat with natural air is more difficult than other grains such as soybeans or sunflower seeds.

Aeration helps to avoid the risk of insect development in dry grains, since they develop at high temperatures (between 25º and 33º). The objective is to keep the product between 17º-25º. Moreover, when the development of insects is interrupted, the activity of fungi is also reduced.

Aeration must be used frequently to maintain the temperature at the appropriate values, thus avoiding grain heat. We must be careful not to store wet wheat, since biological activity raises the temperature of the product.

In order to avoid over-drying, we can install an automatic aeration control that benefits from operating at the optimal hours of the day.

When grain cannot be cooled by ambient air, either due to the season of the year or to the geographical area, it is necessary to use artificial refrigeration, which cools the product through refrigeration equipment that transforms the ambient air and introduces it into the silo at a temperature lower than the ambient temperature and also allows control of the moisture content in the air, thus avoiding over-drying or re-wetting .

DRYING

Drying is the process that reduces the moisture content of the grain to a safe level for storage.

The final quality of the grain can be affected by:

- Excessive grain temperature inside the dryer.

- Long exposure time at high temperatures.

- High drying rate and/or high cooling rate (rapid cooling).

The quality damage will depend on the grain type and its end use. In the case of wheat, if the gluten proteins are damaged by the high drying temperatures, the process is irreversible, so it is recommended that the temperature of the grain never exceed 43º inside the dryer.

PEST CONTROL

The development of microorganisms and insects has a negative influence on the quality of the stored grain and can cause serious qualitative losses such as:

- Reduction in the grain weight.

- Increase in the percentage of damaged grains.

- Decreased germination capacity of the seeds.

To prevent infestation, the main recommendations are the following:

- Thorough cleaning of the storage plant.

- Treatment of the empty facility before receiving the new harvest.

- Cooling of the grains by means of aeration or refrigeration.

Prevention must be carried out in a sustained way over time: before, during and after the arrival of the grain to the silo. Constant monitoring will allow you to make the best decision at the right time.