The soybeans spoilage is a process irreversible and inevitable, but it can be delayed. In this article we will explore the less harmful conveying system for soybeans and the recommendation to separate the damaged grains before storage.

The handling of soybeans involves conveying and transporting from the farm to end-user. It is possible for soybeans to be handled as many as fifteen times from the time they leave the farm until processing into oil and meal. This number may increase to as high as twenty for exported material.

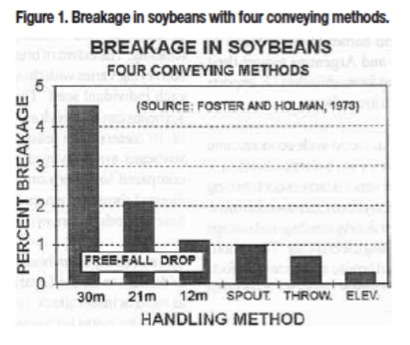

The structure of a soybean seed makes it susceptible to splitting and breakage during mechanical handling. The extent of breakage in soybeans during conveying varies with the impact force imposed on each individual seed. The least breakage occurs when soybeans are conveyed in a bucket elevator as compared to other conveying methods.

The previous image shows the extent of soybean breakage with four methods of conveying: the first one represents the percentage of breakage of the grain in a free fall of 30, 21 and 12 meters.

Regarding conveyors, belt conveyors should be a essential part of the soybean storage process. This kind of conveyors can move large volumes of grain over long distances without damaging the product, so it should be used for loading and unloading process in any soybean storage plant.

The storage of soybeans is affected by the degree of damage to the seed coat and by other factors such as mold or insect attack. It is therefore important to inspect soybeans for mechanical and other forms of damage prior to storage. If the amount of broken or split soybeans is very high, it may be prudent to separate the broken or split grains by sieving. This material can then be used first as opposed to long-term storage with the original stock.

DOWNLOAD PDF FILE with more information and recommendations for the storage of soybeans and soybean meal in a metal silo