Timely detection of issues in soybeans stored in a metal silo is crucial to ensuring their quality and preventing losses. Here are some key indicators to watch for:

Heating

One of the indicators that will help you to detect any possible problems with the products storage inside the silos is Heating.

According to the Department of Grain Science and Industry (Kansas State University), heating is the most common indicator of a problem in stored grains and oilseeds. High grain temperatures normally indicate either microbial or insect activity. If left unchecked, this may lead to heat-damaged or charred grains due to the phenomenon of stack burning.

Because of this danger, hot spots in stored soybeans must be cooled or dissipated before they reach the critical level. If no action is taken when heating in soybeans occurs, either the product will be lost by stack burning (charring) or at worst, the entire facility will be lost through fire.

Warning! Aerating soybeans when fire has already started makes the situation worse.

A temperature monitoring system in soybean storage silos is essential. Immediate corrective measures for heating cannot be over-emphasised.

Change in color

One of the indicators that will help you to detect any possible problems with the products storage inside the silos is the change in color and general appearance.

In general, sound soybeans are plump with bright uniform tan and not green color and free from unusual spots and shriveled appearance. Discolored soybeans usually indicate inferior quality and lower market value. The change in color is usually associated with mold invasion accompanied by microbial respiration and subsequent heating. This deterioration process can be detected by periodic drawing of samples from the stored soybeans as part of an integrated approach to quality maintenance.

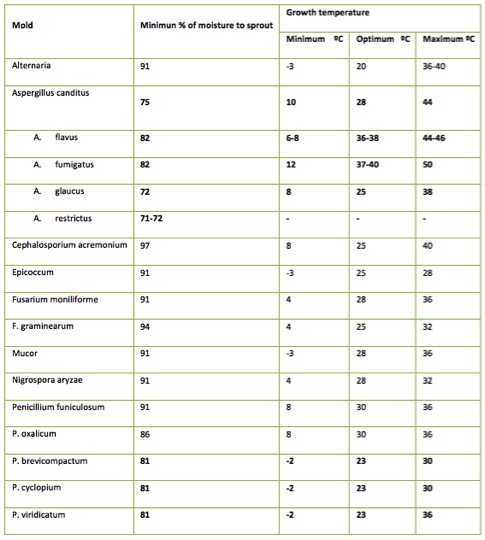

Change in color is mainly caused by the appearance of mold. The following table shows the minimum % of humidity at which the different molds can develop, as well as the minimum, optimum and maximum temperatures at which they develop. Most of them have an optimum between 25 and 28ºC.

If we control temperature and moisture, we will avoid change in color, therefore our product will have a higher market value.

Preventive measures:

- Cooling the grain either by aeration or use of a portable cooling unit.

- To transfer the grain to another silo thus breaking any hot spots present and cooling the soybeans during the conveying process. However, this should be done only as a last resort since it is costly and will increase the amount of broken or split soybeans.

Musty odor

Another of the indicators that will help you to detect any possible problems with the products storage inside the silo is the mustiness and off-odor condition.

Musty odor usually indicates an advanced stage of insect or mold infestation and should be dealt with immediately.

What to do when it happens:

- The soybeans should be aerated to remove the bad odor and cool the material. Beans should then be used at the earliest opportunity.

- The grain should be fumigated immediately if insects are present. A sharp odor may indicate rancidity due to chemical changes in the oil component.

Lumping and caking

Finally, another indicator that will help you to detect any possible problems with the soybeans stored inside the silos is Lumping and caking.

Lumping and caking indicate a very advanced stage of fungi invasion in soybeans and soybean meal. In metal silos, caking usually occurs on the bin walls as a result of sweating or moisture condensing on the inner surface of the cold bin wall. The condensing moisture is absorbed by the adjacent grains resulting in either sprouting or mold growth.

References: Department of Grain Science and Industry, Kansas State University, USA